4. Signifificance and Use

4.1 Transparent plastic materials, when used as windows or

enclosures, are subject to wiping and cleaning; hence the

maintenance of optical quality of a material after abrasion is

important. It is the purpose of this test method to provide a

means of estimating the resistance of such materials to this type

and degree of abrasion.

4.2 Although this test method does not provide fundamental

data, it is suitable for grading materials relative to this type of

abrasion in a manner which correlates with service.

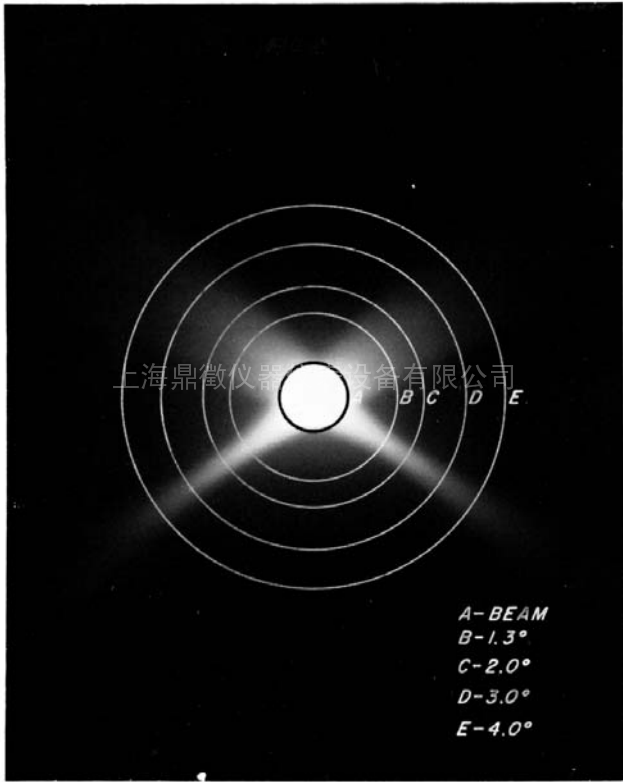

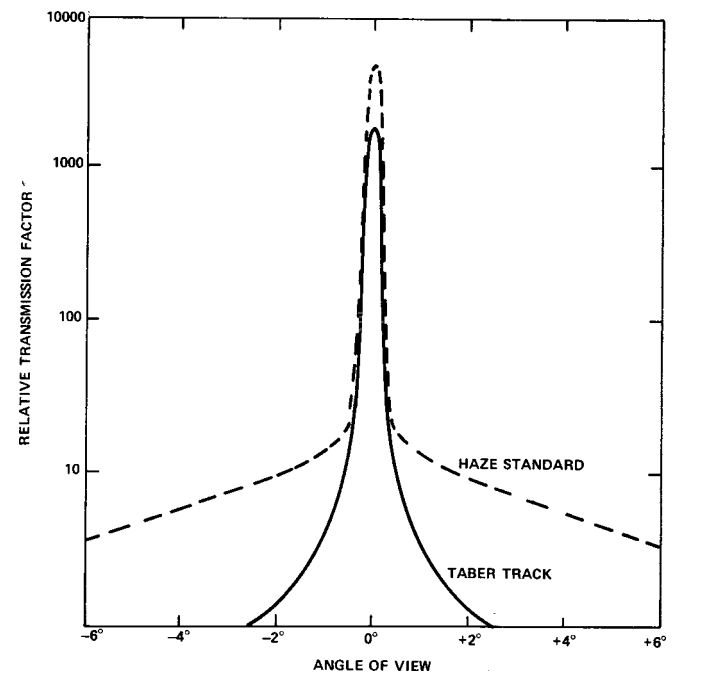

4.3 Comparison of interlaboratory data or the specifification

of a “haze” value has no signifificance if the hazemeter

requirements given in 5.4 are not used. This is because light

diffused from the surface of a Taber track is scattered at a

narrow angle (Fig. 1 and Fig. 2) while light diffused internally

by a specimen is scattered at a wide angle. In many hazemeters,

when a diaphragm is inserted to limit the light beam to the

width of the abraded track, the specular beam at the exit port

becomes smaller. The dark annulus will then be greater than the

0.023 6 0.002 rad (1.3 6 0.1°) requirements of Test Method

D 1003. Since a large percentage of the narrow-angle forward

scattered light will not impinge on the sphere wall, “haze”

readings become smaller. For hazemeters that have not been

properly adjusted, the magnitude of this reduction is dependent

both on the integrating sphere diameter and the reduction of the

entrance beam.

4.4 For many materials, there may be a specifification that

requires the use of this test method, but with some procedural

modififications that take precedence when adhering to the

specifification. Therefore, it is advisable to refer to that material

specifification before using this test method. Table 1 of Classi-

fification System D 4000 lists the ASTM materials standards that

currently exist.

4.5 For some materials, abrasion tests utilizing the Taber

abraser may be subject to variation due to changes in the

abrasive characteristics of the wheel during testing.

4.5.1 Depending on abradant type and test specimen, the

wheel surface may change (that is, become clogged) due to the

pick up of coating or other materials from test specimens and

must be cleaned at frequent intervals.

4.5.2 The type of material being tested and the number of

test cycles being run is known to sometimes inflfluence the

temperature of the running surface of the wheel with an affect

on the fifinal haze measurement. To reduce any variability due to

this temperature effect, stabilize the wheels surface tempera

ture prior to performing actual measurements. This shall be

accomplished by conducting multiple refacings on an ST-11

refacing stone, followed by a test on the sample material to be

tested (with results to be discarded).

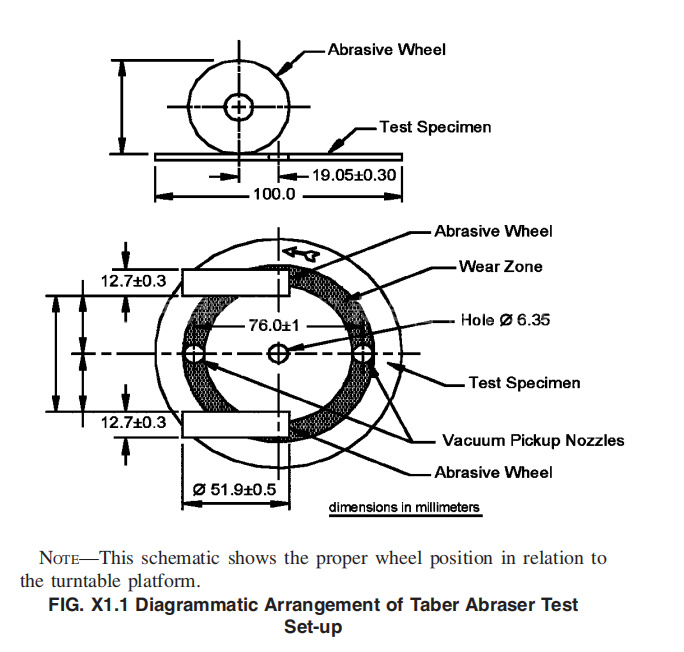

5. Apparatus

5.1 Abrader—The Taber abraser or its equivalent, consist

ing of the following elements:

5.1.1 A horizontal turntable platform; comprised of a rubber

pad, clamp plate, and nut to secure the specimen to the

turntable.

5.1.2 A motor capable of rotating the turntable platform at a

speed of either 72 6 2 r/min for 110v/60Hz or 60 6 2 r/min for

230v/50Hz.

5.1.3 A pair of pivoted arms, to which the abrasive wheels

and auxiliary masses (if used) would be attached; loads of 500

or 1000 gf on the wheels are obtained by use of changeable

weights.

NOTE 5—Without auxiliary masses or counterweights applied, each

arm will apply a load against the specimen of 250 gf per wheel (exclusive

of the mass of the wheel itself).

5.1.4 A vacuum suction system and vacuum pick-up nozzle

to remove debris and abrasive particles from the specimen

surface during testing. The height of the vacuum pick-up

nozzle shall be adjustable, and the nozzle openings shall be 11

mm [7⁄16 in.] in diameter.

NOTE 6—The nominal nozzle openings are 8 mm [5⁄16 in.] and can be

enlarged following the instructions shown in Appendix X2.

5.1.5 A counter to record the number of cycles (revolutions)

made by the turntable platform.

5.2 Refacing Stone—The fifine side of a ST-11 refacing stone

(or equivalent) shall be used for refacing the abrasive wheels.

It is important that the turntable platform runs true on the

abraser and that the refacing stone lies flflat on the turntable

platform.

5.3 Abrasive Wheels—The grade of wheel designated CS-

10F5 shall be used, and shall meet the following requirements

at the time of the test:

5.3.1 The wheel shall be 12.7 6 0.3 mm wide and have an

external diameter of 51.9 6 0.5 mm when new, and in no case

less than 44.4 mm, and

5.3.2 The wheel shall not be used after the date stamped on

it.

5.4 Hazemeter—An integrating sphere photoelectric pho

tometer, as described in Test Method D 1003, shall be used to

measure the light scattered by the abraded track. If haze

measurements are made with other devices or by other meth

ods, a correlation shall be established with the results obtained

with the apparatus and method described in Test Method

D 1003.

5.4.1 An aperture or diaphragm shall be centrally inserted in

the haze measuring apparatus to center the light beam on the

abraded track and limit it to a diameter of 7 6 1 mm [0.28 6

0.04 in.] at the specimen.

5.4.2 When the reduced light beam is unobstructed by a

specimen, its cross section at the exit port shall be approxi

mately circular, sharply defifined, uniformly bright, and concen

tric within the exit port, leaving an annulus of 0.023 6 0.002

rad (1.3 6 0.1°) subtended at the entrance port.

5.5 Specimen Holder—A suitable holder shall be used to

permit positioning the abraded specimen on the hazemeter so

that the light beam is centered in the abraded track and the

specimen is flflush at the measurement port.

6. Test Specimens

6.1 The test specimens shall be clean, transparent disks

approximately 100 mm in diameter or plates approximately

100 mm square, having both surfaces substantially plane and

parallel. They may be cut from sheets or molded in thicknesses

up to 12.7 mm [1⁄2 in.]. A 6.3-mm [1⁄4-in.] hole shall be

centrally drilled in each specimen. Three such specimens shall

be tested per sample, except for interlaboratory or specifification

tests when ten specimens shall be tested.

7. Calibration

7.1 Verify calibration of the Taber abraser as directed by the

equipment manufacturer (see Appendix X1).

8. Conditioning

8.1 Conditioning—Unless otherwise specifified, condition

the test specimens at 23 6 2°C [73.4 6 3.6°F] and 50 6 5 %

relative humidity for not less than 40 h prior to test in

accordance with Procedure A of Practice D 618. In cases of

disagreement, the tolerances shall be 61°C [61.8°F] and

62 % relative humidity.

8.2 Test Conditions—Conduct tests in the standard labora

tory atmosphere of 23 6 2°C [73.4 6 3.6°F] and 50 6 5 %

relative humidity, unless otherwise specifified. In cases of

disagreements, the tolerances shall be 61°C [61.8°F] and

62 % relative humidity.

9. Standardization of Abrading Wheels

9.1 To ensure that the abrading function of the wheels is

maintained at a constant level, prepare the abrading wheels

prior to each test.

9.1.1 Mount the wheels on their respective flflange holders,

taking care not to handle them by their abrasive surfaces.

9.1.2 Select the load to be used and affix it to the abraser. If

no load is specifified, use a load of 500 gf (per wheel).

9.1.3 Mount an ST-11 refacing stone (or equivalent) on the

turntable, fifine side up, and secure using the nut.

9.1.4 Lower the vacuum nozzle and adjust its height to

within 0.8 to 1.6 mm [1⁄32 to 1⁄16 in.] of the refacing stone. Set

the vacuum suction force to 100.

9.1.5 Lower the arms so the wheels contact the surface of

the ST-11 refacing stone.

9.2 Before abrading each specimen, reface the wheels for 25

cycles on the fifine side of the ST-11 refacing stone. After

refacing, use a soft bristle, anti-static brush to lightly brush the

wheel surfaces to remove any loose particulate matter before

abrading a specimen. (Warning—Do not touch the running

surface of the wheels after they are refaced. New wheels or

wheels trued using a diamond tool refacer, must fifirst be broken

in with 100 cycles on the fifine side of the ST-11 refacing stone

followed by a test on the material to be evaluated (results to be

discarded).)

NOTE 9—A brush found suitable for this purpose has been described as

follows: Having a width of two inches with tuft spacing of 0.25 inches. It

is a soft-fifiber, static-dissipative brush manufactured from an acrylic fifiber

(0.0015 inch fifilament diameter) that has been chemically bonded with a

layer of copper sulfifide to produce a resistance of 3–5 times 10-4 ohms per

centimetre.

NOTE 10—The fifine side of the ST-11 refacing stone has a limited life

and must be replaced after 10,000 cycles (approximately 400 refacings).

9.2.1 A thin fifin of wheel material will sometimes form on

the left hand edge of the wheel as the main body of the wheel

wears down. To remove, gently rub the edge of the wheel using

your fifinger. Avoid touching the running surface of the wheel.

9.2.2 The maximum allowed time between refacing and

testing shall not exceed two minutes.

10. Procedure

10.1 Before testing, remove any protective masking mate

rial from the specimen. If required, clean the specimen using a

practice recommended by the manufacturer. Handle test pieces

by their edges to prevent contamination of their surfaces.

10.2 Place the unabraded specimen in the hazemeter sample

holder with the side to be abraded facing the entrance port of

the integrating sphere. Measure the haze percentage (initial

haze) of the specimen at a minimum of four equally spaced

points in the unabraded area. The results shall be averaged for

each specimen.

NOTE 11—As an operational qualifification step for the instrumental

measurement of transmission haze, it is recommended to measure the haze

percentage value with no sample present and verify that the reading of the

hazemeter is 0. The sample holder must be removed during this measure

ment.

10.3 Mount the specimen on the abraser turntable platform

with the side to be abraded facing up. Secure using the clamp

plate and nut.

10.4 Select the load to be used and affix it to the abraser.

Lower the vacuum pick-up nozzle and adjust the height to

within 0.8 to 1.6 mm [1⁄32 to 1⁄16 in.] of the specimen surface.

Set the counter to zero and program the appropriate number of

cycles. Start the abraser and subject the specimen to abrasion

for a selected number of cycles. Use an abrasion of 100 cycles

with the 500 load, unless otherwise specifified.

remaining particulate. For those materials where IPA inflfluences

the surface characteristics, use deionized water or a cleaning

solution that is compatible with the sample.

10.6 Place the abraded specimen in the hazemeter sample

holder with the abraded track against the entrance port of the

integrating sphere (facing away from the light source). Mea

sure the haze percentage of the transmitted light that is diffused

by the abraded track (fifinal haze) on at least four equally spaced

intervals along the track. The results shall be averaged for each

specimen. The specimen holder shall be positioned so that no

portion of the light beam is within 1 mm of the inside or

outside edge of the track.

10.6.1 Percent haze, as defifined by Test Method D 1003, is

calculated as follows:

haze 5 [Td / Tt# 3 100 (1)

where:

Tt

= total transmittance

Td

= diffuse transmittance

NOTE 14—Subjective comparisons may be made by visually comparing

abraded specimens with a measured, abraded standard.

10.7 The initial haze percentage of the unabraded specimen

determined by 10.2 shall be subtracted from the fifinal haze

percentage of the abraded sample as measured by 10.6. The

difference represents the light scatter resulting from abrading

the specimen.

11. Interpretation of Results

11.1 The lower the percent haze difference, the more resis

tant the specimen is to abrasive damage.

12. Report

12.1 Report the following information:

12.1.1 Change in percentage of haze as calculated by 10.7,

12.1.2 Number of specimens tested,

12.1.3 Load and the number of cycles used, if other than

specifified in 10.4,

12.1.4 Wheel cleaning interval(s), if clogging is an issue,

12.1.5 Temperature stabilization details (in accordance with

4.5.2), if applicable,

12.1.6 Cleaning solution used, if applicable,

12.1.7 Rotational speed of turntable platform,

12.1.8 Plot of the percentage of light scattered versus cycles

abraded, if more than one number of cycles is used, and

12.1.9 Description of the integrating sphere photometer

including: sphere geometry; exit light beam diameter with and

without the diaphragm inserted; and location of the diaphragm

in the light beam. Alternatively, report the make and model of

the hazemeter used.

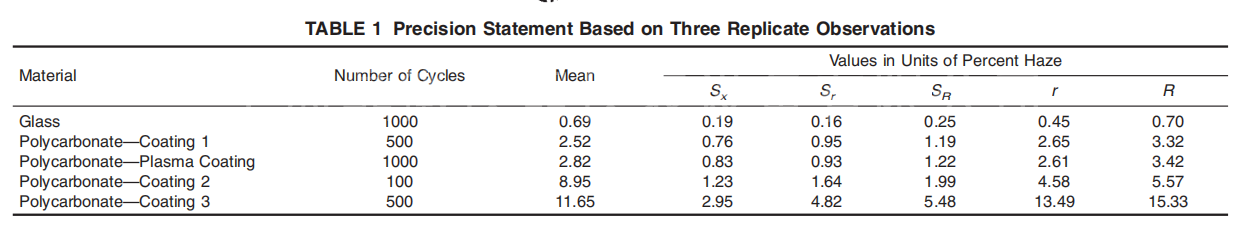

13. Precision and Bias

13.1 Table 1 is based on a round robin conducted in 2004,

involving fifive materials tested by fifive laboratories. Each lab

made six (6) determinations for each material and cycle

combination. It should be noted that the test procedure used for

the round robin involved higher reface cycles, and no consid

eration was given to the useful life of the ST-11 refacing stone.

13.1.1 In Table 1 for the materials indicated:

Sr = pooled within-laboratories standard deviation of the

mean for three or ten specimens,

SR = total among-laboratories standard deviation of the mean

for three or ten specimens,

r = 2.83 Sr (see 13.2), and

R = 2.83 SR (see 13.3).

Other materials may give somewhat different results.

13.2 Repeatability—In comparing two averages for the

same material, obtained by the same operator using the same

equipment on the same day, the average should be judged not

equivalent if they differ by more than the r value for that

material and condition.

13.3 Reproducibility—In comparing two averages for the

same material, obtained by different operators using different

equipment, the averages should be judged not equivalent if

they differ by more than the R value for that material and

condition.

13.4 The judgments in accordance with 13.2 and

|