TEST METHOD

Adhesion, water spraying under high pressure

Paints and enamels

Orientation

This issue differs from issue 1 in that:

- scribing shall be made after moisture exposure instead of before

- calibration shall be made on low-density polyethylene plastic

- tolerances for certain calibration parameters have been added

- a requirement has been added stating that manual high-pressure cleaning may only be performed after agreement with Volvo

- a number of clarifications have been made.

1 Scope and field of application

This test method is used for assessing the adhesion between paint films and between paint film and substrate respectively. The method is intended to simulate the strain and load that the paint films are subjected to during high-pressure cleaning.

2 Apparatus and test object

− Test equipment of high-pressure type, brand NIFAB,

model HTT-1, or equivalent test equipment

Water pressure: min. 150 bar

Spraying distance: 0-150 mm

Sweeping frequency: 1 sweep/s

Water temperature: 50 ± 5 °C

Spray nozzle: (flat jet 25°) No 2506

Lance length: 300 ± 50 mm

Test piece holder with

centre hole, size of hole: ∅ 40 mm

− Test object

1) Spray nozzles meeting this specification can, for

instance, be purchased from Spraying Systems

Co.

a) Test panel in accordance with STD 1021,5211 (100 x 200 mm) of the substrate in question, surface coated with the relevant paint system. A minimum of two panels shall be tested. A minimum of three crosses distributed between the two

panels shall be tested.

b) Test part of the relevant substrate, surface coated with the relevant paint system. In order to have significant results, test pieces should be taken from different areas on at least two test parts. A minimum of four crosses shall be tested for each part.

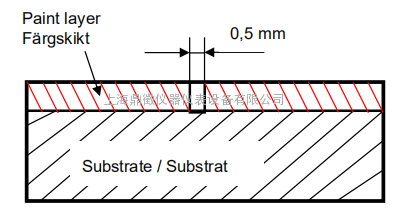

− Scribing tool, edge width 0,5 mm and geometry according to STD 1021,2.

3 Preparation for test

The test panels shall be conditioned in accordance with STD 1021,1. Before testing the adhesion, an initial paint damage shall be made on the test object by scribing two 0,5 mm scribe lines using a scribing tool. The scribed lines shall be made down to the

substrate, at right angles to each other to create a cross, see fig. 1. The scribed lines shall extend outside the test area. Each scribed line shall be approx 60 mm. A cross section of a scribed line is shown in fig. 2.

IMPORTANT – The edges of the scribed lines must

be at right angles to the substrate.

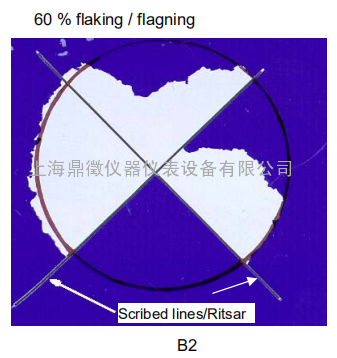

Fig. 1 Principle layout / Principskiss

Fig. 2 Cross section of test piece with scribed line

When the adhesion test is to be made after moisture exposure (wet adhesion), the test object shall first be exposed in a tropical cabinet in accordance with STD 423-0018 for the period specified in the requirements specification.

For metal substrates, the testing shall be performed immediately after exposure, without any recovery. In practice, this means that the panels shall be stored

maximum 60 min in a vessel filled with water of room temperature to keep them humid until testing.

As far as plastics substrates are concerned, they shall be stored for 1 h in a constant-temperature controlled cabinet at standard atmosphere (23 ± 2 °C, 50 % RH) instead of storage in a water-filled vessel. This shall be done to allow the material to recover. The testing shall then take place within approx. 15 min.

The scribing shall be made after the moisture exposure.

4 Test procedure

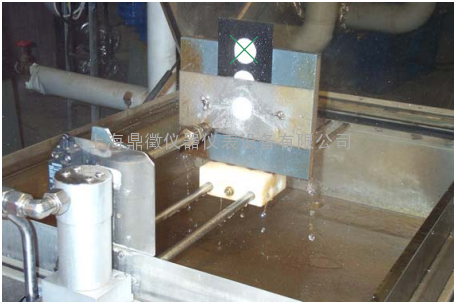

Place the test object in the test-piece holder. Then fix the test-piece holder’s hole (∅ 40 mm) centrally above the initial damage. It is important that the cross is

correctly positioned in front of the jet, see fig. 3. The following parameters apply; the nominal values are target values:

− The water jet shall sweep over the test surface (± 20 mm) with an angle of deflection of 5,6° from the nozzle tube’s centre of rotation (N.B. No parallel displacement)

− Distance between nozzle and test surface (90°): 100 ± 3 mm

− Water pressure: 120 ± 3 bar

− Water flow: 15,0 ± 0,3 l/min

− Water temperature: 50 ± 5 °C

− Number of sweeps during 30 s: 30 ± 2

− Sweeping width: ± 20 mm (diameter of the test piece holder’s centre hole)

Manual spraying under high pressure complying with the above parameters is also possible. This shall only be used after agreement with Volvo.

5 Assessment

After completed test, the object shall be wiped dry and the extension of the paint damage shall be established. The test result shall be given in per cent flaked

paint surface. 100 % is defined as the circular area (Ø 40 mm) centred on the scribed cross, see fig. 1, (1256 mm2).

The requirement shall be met for each scribed cross. Mean values for the entire part/panel shall NOT be calculated.

6 Report

The test report shall include the following:

a) Type and designation of test material

b) Test result in per cent (for each test object respectively). The number of rejected samples shall be noted.

c) Testing in accordance with STD 423-0015.

7 Calibration

Unless otherwise specified, calibration and inspection of the nozzle’s spray pattern shall be made with an interval of 90 days.

Calibration is performed by subjecting a test panel (approx. 100 mm x 200 mm) of low-density polyethylene as per STD 1211,05 or equivalent material to high-pressure cleaning for 30 s without the use of a test-piece holder. The nozzle must not oscillate. The following parameters apply:

− Angle between nozzle and test surface: 90°

− Distance between nozzle and test panel: 100 mm ± 3 mm

− Water pressure: 120 bar ± 3 bar

− Water flow: 15,0 ± 0,3 l/min

− Water temperature: 50 ± 5 °C

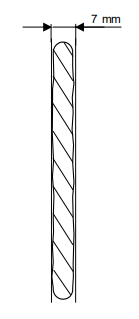

The nozzle’s spray pattern is determined by measuring the length and width of the damage on the test panel caused by the spraying as well as checking its appearance.

To be approved, the spray pattern shall be continuous, have a length of 63,0 ± 5 mm and a width of min 3,0 mm, and it shall be contained between two parallel

lines, 7,0 mm apart (see fig. 4).

Fig. 3 The cross mark shows schematically the position of the scribed lines in relation to the vertical flat jet

Fig. 4 Damage from spray

蒸汽喷射试验机满足测试规范汽车厂家:宝马、奔驰、通用、大众、福特、沃尔沃等规范(AA-0136、DIN 55662、ISO16925,DBL 7381,GM9531P、PV1503、VOLVO STD 423-0015,VOLVO VCS 1029 54719、FLTM BO 160-04、MS210-07,PSA D23 5376,Renault D25 2018/-A-2001 ,GMW16745-2012方法B,TPJLR-52.561-2009)

|